Did you see our favorites?

Anodized aluminum is highly long-lasting, owing to the anodizing process. This technology helps to create a weather-resistant, tarnish-resistant surface that may last years, but like any metal, anodized aluminum will scratch and fade with time. Cleaning on a regular basis can help to keep the metal bright and its sheen natural.

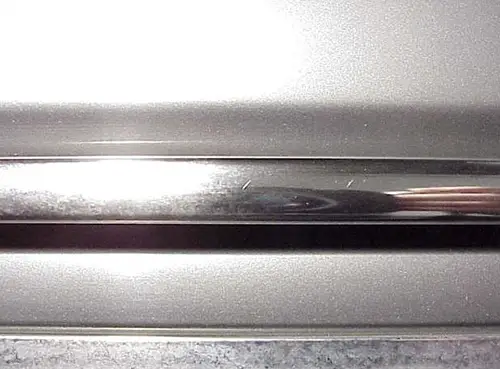

Anodizing is a beautiful aluminum finish until it is damaged. It’s not simple to remove the previous layer and polish it. This technique makes a weather-resistant surface that is both efficient and successful, with the top layer lasting for a long time while preventing tarnishing. You must replace as well as polish a worn, scratched, or stained surface.

Aluminum is the most popular metal for anodizing because of its mechanical properties and chemical composition. Aluminum oxide provides a protective coating that protects the component’s surface hardness, corrosion resistance, scratch resistance, and visual appeal. Because the anodized aluminum layer forms a part of the underlying metal, it doesn’t chip or peel off like other coated or painted finishes.

Naturally, when aluminum is oxidized, its surface creates a protective layer. Yes, aluminum anodizing is a highly controlled application of this natural phenomenon. The formation of anodic oxide structure during the aluminum anodizing process results in a porous layer on the part’s surface. This pore-bearing material may be dyed and sealed as well.

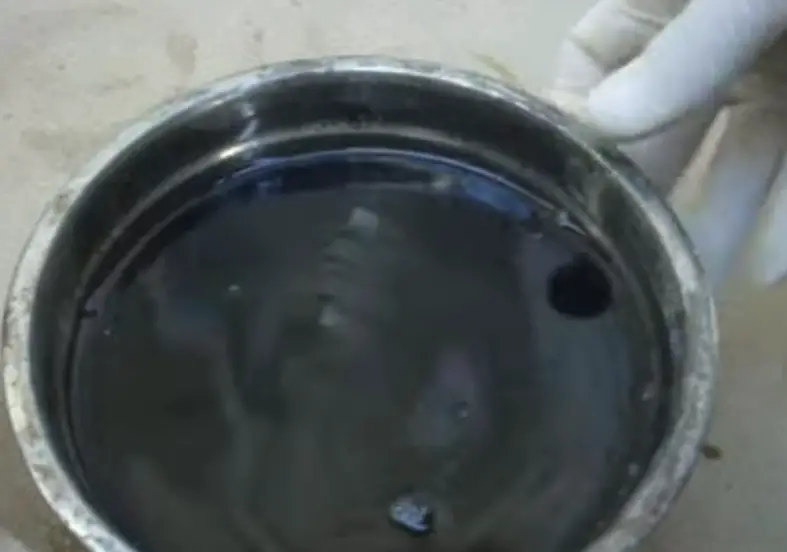

The basic mechanism behind aluminum anodizing is to plunge the material into an electrolyte solution that contains oxygen ions, which causes aluminum to oxidize.

AL-NEW Aluminum Restoration Solution removes the chalky oxidation on painted and anodized aluminum, as well as fiberglass surfaces impacted by heat and UV exposure. Aluminum Restoration Solution cleans aluminum and other painted metals. It is designed to be used on metal surfaces around the house outdoors, such as patio furniture, garage doors, light fixtures, and more.

AL-NEW Aluminum Restoration Solution removes the chalky oxidation on painted and anodized aluminum, as well as fiberglass surfaces impacted by heat and UV exposure. Aluminum Restoration Solution cleans aluminum and other painted metals. It is designed to be used on metal surfaces around the house outdoors, such as patio furniture, garage doors, light fixtures, and more.

Autosol Polish for Anodized Aluminum is a specially formulated polish containing the finest of polishing substances to achieve optimum cleaning results on all types of anodized aluminum without harming the anodized surface. Developed with and tested by the company LSL Motorradtechnik in Krefeld.

Autosol Polish for Anodized Aluminum is a specially formulated polish containing the finest of polishing substances to achieve optimum cleaning results on all types of anodized aluminum without harming the anodized surface. Developed with and tested by the company LSL Motorradtechnik in Krefeld.

Things You Will Need

Fill the pan with warm water and sodium hydroxide, then drain away the excess liquid. 1 tablespoon of cleaner is enough for a gallon of water. The water must be sufficient for dipping your item completely.

Plunge the aluminum component into the drain water. Because gases are hazardous, there must be air movement over the pan. It’s possible that breathing them will do damage to your health. When bubbles form on the surface of the metal, lift it out to remove “smut,” a chemical residue that can develop in this process. If the de-anodizing procedure is taking too long, you may need to increase the quantity of cleaner used. To get a clean surface on the aluminum piece, you’ll need to remove any smut from it

[product_card_static label=”Flitz LQ 04535-6A-6PK” link=”https://www.amazon.com/dp/B00DOUQMGE/?tag=shmulshmulcleaninglab-20″ image=”https://cleaningproductslab.com/wp-content/uploads/2021/09/B00DOUQMGE.jpg” title=”Has the industrial strength cleaning power to protect and polish metal, plastic, fiberglass, aluminum and chrome. Even removes rust, graffiti and restores headlights. Gentle enough to use in kitchen, bathroom, and even on jewelry.” btn_color=”#ffa226″ btn_name=”CHECK PRICE”]

Once the pieces are flat, uniform, and free of flaws, blemishes and stains vanish. It’s time to get the item out of the water. Rinse thoroughly with fresh water and allow it to dry for a while. Make sure there aren’t any anodized marks on the aluminum piece after this procedure. Otherwise, you may repeat the process by rubbing the piece, rinsing it again, and allowing it to dry naturally.

Using 800 grit papers, you can sand the aluminum piece and remove scratches. Silicon oxide sandpaper is superior to other sandpaper in that it works more quickly and provides a long-lasting result on aluminum products. Now polish the surface to make it seem brighter and shinier.

You may re-polish the aluminum item. If you don’t, it might appear soft. Polishing metal is a difficult job. To perform this function, you’ll need knowledge and experience. You may need some equipment to polish the aluminum surface. Waxing and coating can help to increase durability and lifespan of aluminum items by adding protection or enhancing them aesthetically

If you don’t want your jewelry to tarnish, a coat of wax is advised and works well for preventing staining. Clear lacquer and enamel in a spray also seems to help, allowing your item to survive the rigorous and durable environment. After spraying your piece, don’t touch it and allow it to dry fully.

Aluminum has long been recognized as a strong metal, but the anodization process makes it three times tougher. This new aluminum surface will not even scratch or peel off.

The finish of this alloy is also enduring, so it doesn’t discolor when exposed to high heat. The process that prevents color change is adjustable from matte to glossy and includes a range of colors. It’s lighter than other comparable metals including stainless steel and far less expensive to produce. It may be found in coffee makers, microwaves, architecture, and transportation.

Anodized aluminum may be more durable, but mishandling it is the quickest route to damage it. When cleaning anodized aluminum, mild cleaners and equipment are the best option for removing dirt and debris.

When cleaning anodized aluminum, use a mild soap like Castile. Cleaning chemicals with a neutral pH are the most safe and efficient.

Fill a container halfway with warm water to clean an aluminum cookie sheet or other similar item, then add a few drops of mild soap for suds. It’s always a good idea to perform some preliminary testing in a small area before committing fully.

Once you’ve determined the cleaner is good for metal, damp a soft cloth or sponge in the soapy water and use it to clean the entire anodized aluminum product, whether you’re restoring old aluminum windows or your boat trailer.

Soap can be used to cover a broad surface at once.ScotchBrite pads, for example, are fine to use on sites with dirt build-up, such as when you deep clean your vehicle’s or RV’s aluminum wheels.

After you’ve finished cleaning the aluminum, rinse it with clean water. Remove all remaining moisture using a new dry towel or a microfiber cloth.

It’s simple to clean aluminum at home since most individuals already have the supplies on hand. Because of their mild components, homemade aluminum cleaner and polish are frequently safe to use on aluminum and always provide it a brilliant finish.

To clean an aluminum boat trailer or another big item, make the ingredients bigger.

DIY Aluminum Cleaner

Combine all of the ingredients in a medium mixing bowl until they form a paste. After five to ten minutes, spread the paste over the anodized aluminum and let it sit for a few moments. Remove the paste using fresh water and dry off the aluminum with a clean cloth. This is probably the most effective method of cleaning metal pans since it effectively removes accumulated grease and gunk build-up from them. If you have chalky white aluminum siding, this is one way to get rid of brake dust.

Vinegar is a strong cleanser that removes dirt, stains, and grime from fabric. If you have a tiny piece of aluminum, fill your sink with warm water and a reasonable amount of white vinegar. To clean cast iron pots, soak the metal in the vinegar solution for about 30 minutes. After draining the sink, wet down the metal with clean water once again. Allow the aluminum to dry fully before using it again if it’s anodized aluminum shower door or has rusted rim. You’ll be surprised at how well it works!

Anodized aluminum cookware is one of the most frequent anodized aluminum products in our everyday lives, and it’s vital to learn everything there is to know about it. Anodized cookware is sealed so that the metal does not seep into your meals when cooked. It isn’t affected by acidic foods and is scratch-resistant as well as non-stick and heat conducts rapidly. The surface of anodized metal closely resembles stainless steel, making it a great conductor of heat.

The silver anodized cookware, like other anodized aluminum goods, has a number of disadvantages. These products are not suggested for high-temperature cooking. Frequently, dishwashers damage the nonstick surface, and sprays do not react well to it. We always recommend consulting the company’s sitemap to see whether they offer a care guide for their aluminum. Most businesses have comprehensive care instructions for their aluminum on their websites, including specific information. Cleaning anodized aluminum is something that all of us can do on a budget and only takes a few moments out of your day to make it look like new once again.

Anodizing is a process used to alter the chemical composition of metals. It is a chemical conversion technique that results in a hard surface finish on your item. It may be used on a number of different materials, including aluminum, titanium, magnesium, and conductive plastics. It’s durable, dependable, and low-cost. It protects against corrosion by preventing the formation of rusting compounds. Corrosion resistance is excellent, and it’s difficult to remove the anodizing. Cleaning the aluminum is beneficial in order to make it clean and glossy. Anodizing adds beauty to metal by increasing its durability against scratching. It’s utilized in architectural fixtures. Aluminum must be surface cleaned before undergoing anodization.

To polish anodized aluminum, you must first thoroughly clean it. Next, rinse it and then apply a solution such as sulfuric acid to the surface. Oven cleaner will also remove the aluminum anodizing off small objects and may only be used for them. For big things, you may use another method to clean them. The numerous advantages of polishing aluminum anodizing include increased durability and longevity of the material. Some key advantages are listed below:

Anodizing, like all anodic treatments, produces a rough and uneven coating that is susceptible to chemical dissolution in the presence of high or low pH conditions. Aluminum was anodized as a result of its growing use as a material for industrial, commercial, and consumer product production. It is ecologically beneficial and has no negative environmental repercussions.

Did you see our favorites?

CleaningProductsLab.com is a participant in the Amazon.com Services LLC Associates Program. As an Amazon Associate we earn from qualifying purchases.

Amazon and the Amazon logo are trademarks of Amazon.com, Inc. or its affiliates.

The information on this blog is not meant as a substitute for medical advice, and should not be taken as such.